Fairbank Textiles are mixed fibre blenders that produce a range of needled felt products for carpet underlay and other applications.

These products embody a number of circular economy principles within their material selection and production processes to create circular products.

WHAT IS A CIRCULAR PRODUCT?

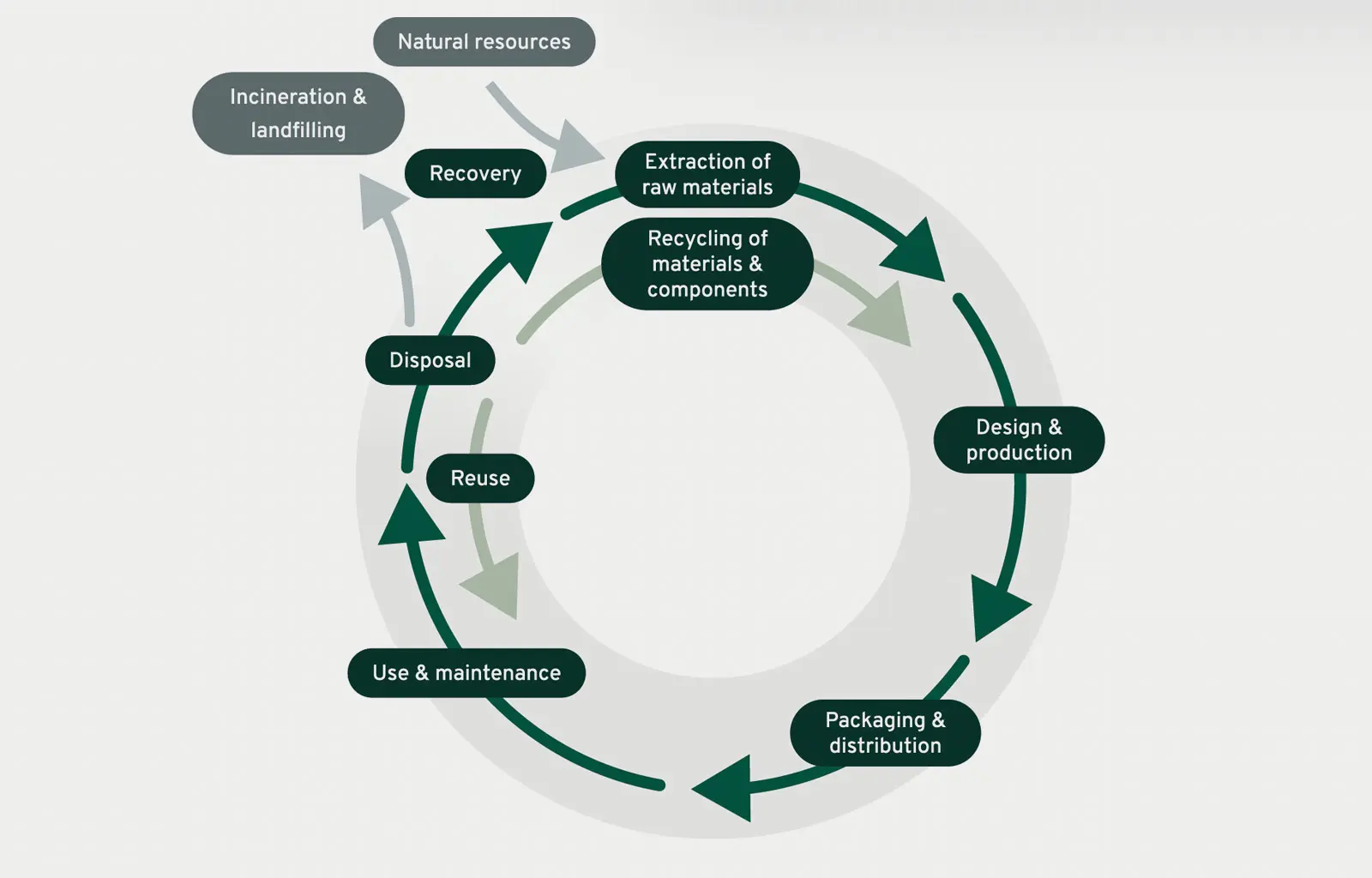

A circular product is a product that is designed and produced within the circular economy principles. This means that the capabilities of repair, reuse, refurbishment, and recycling at the end of life, are built into the design and production process of a circular product, alongside an emphasis on using natural materials which can ultimately cycle back into the earth as biofeedstock.

Considering the full lifecycle of a product is key to enabling a circular product, with every stage of the design and production process implementing circular economy principles.

CIRCULAR THINKING SOLUTIONS

Circular thinking is needed in the product design phase to come up with solutions that enable the creation of a product with a full circular lifecycle.

The circular economy principles of:

- Designing out waste & pollution

- Keeping materials & products in use and

- Regenerating natural systems.

CE principles need to be considered and integrated into the product creation at the initial design stage. All stages of product development need to be included from raw material sourcing, manufacturing processes, to the afterlife disposal of the product.

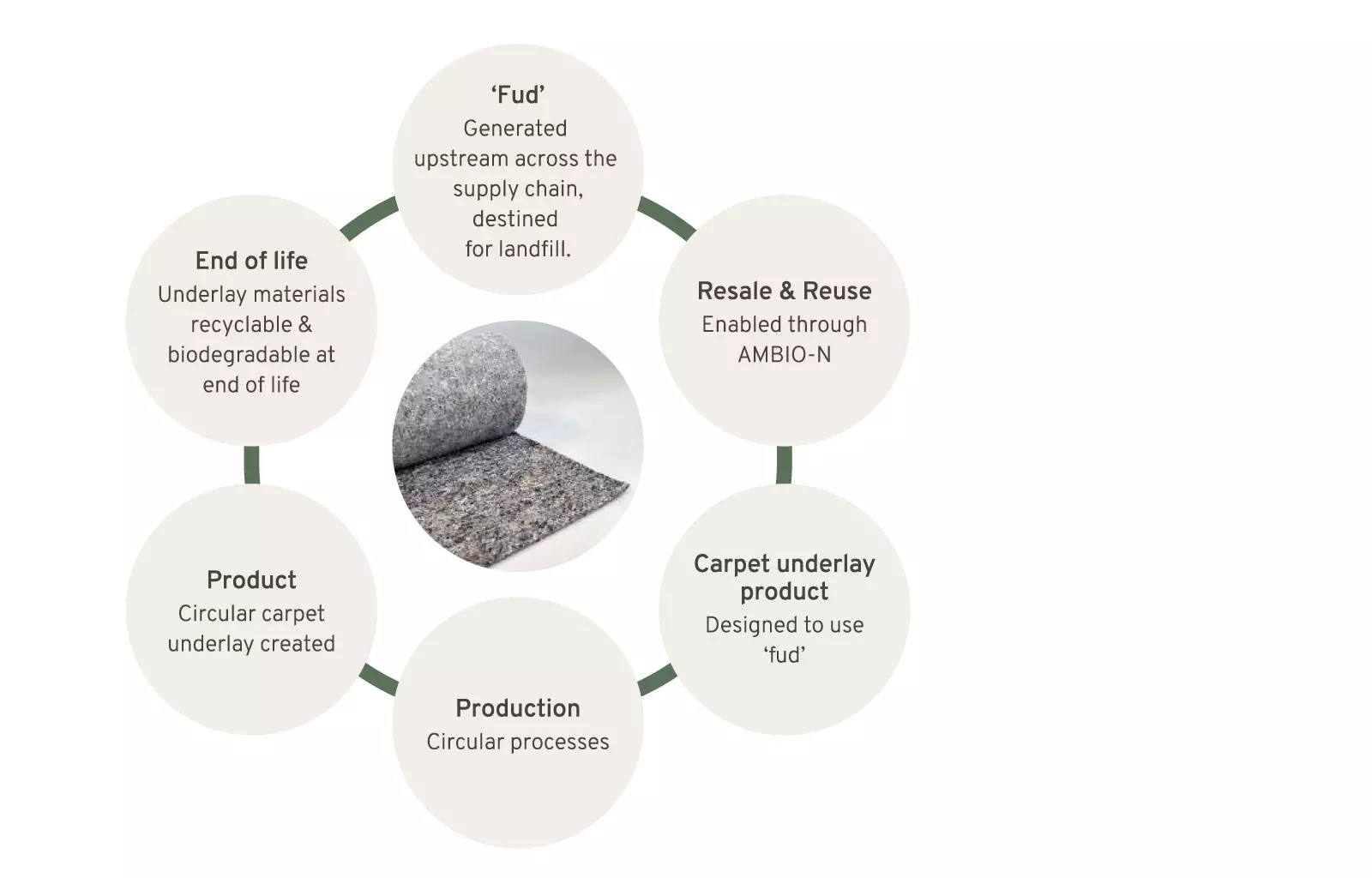

CIRCULAR PRINCIPLES DESIGNED INTO FAIRBANK TEXTILES CARPET UNDERLAYS

- Fairbank Textiles designed their carpet underlay product to utilise waste textiles to create a new, high quality, hard wearing and economical product

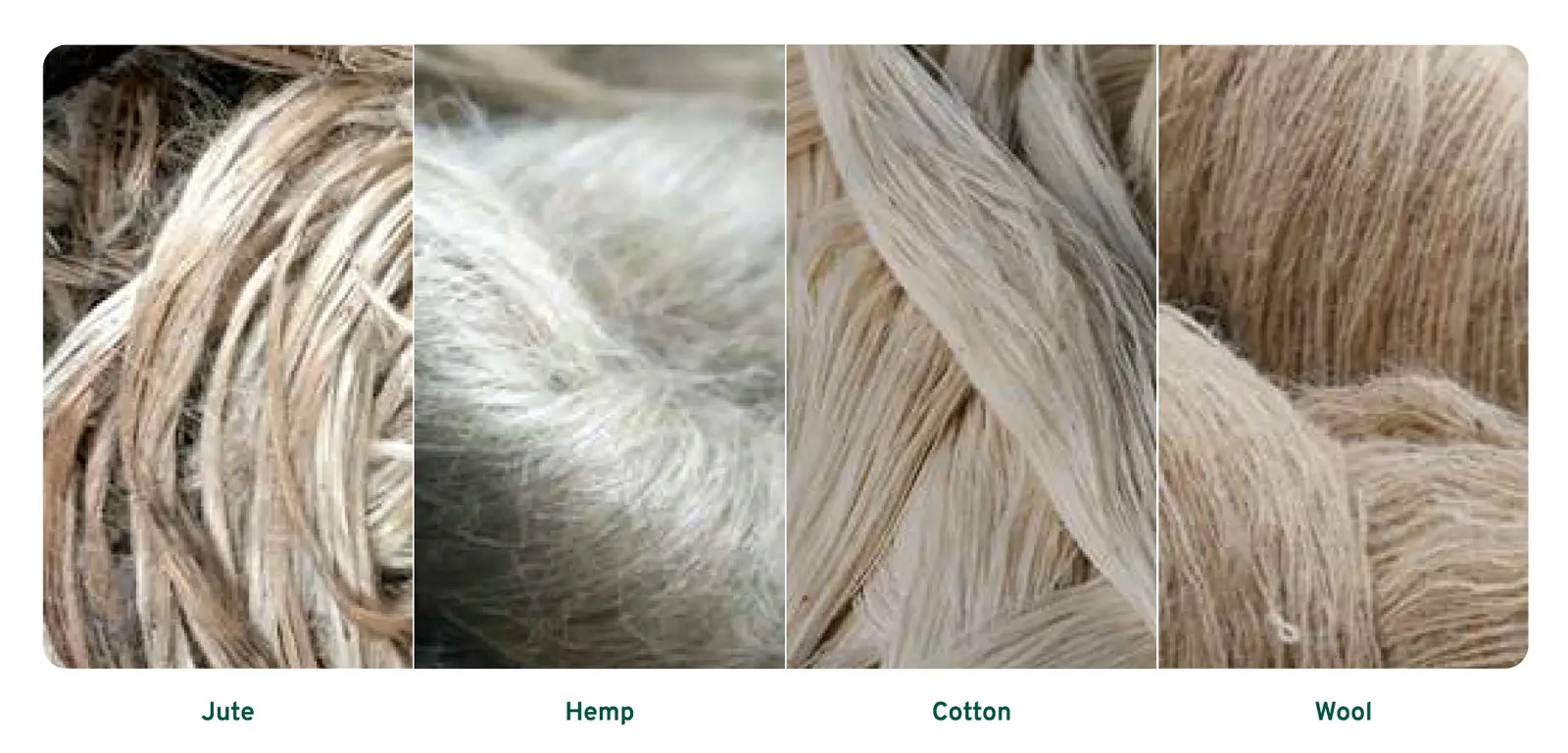

- The waste textiles used to create the wool-rich underlays are a blend of recycled textiles included; ‘fud’ (wool waste), jute (natural material) and recycled synthetics

- The waste textiles have been salvaged from being sent to landfill, instead they are reused and regenerated back into creating new circular products and

- The carpet underlay products are 100% recyclable at the end of their life, creating a circular process that designs beyond the lifespan of the product.

KEEPING IT NATURAL

Natural materials are blended with recycled textiles within the production process, to create products with greater durability that are easily recycled and biodegradable at the end of their life, ultimately feeding back into the regeneration of natural systems.

FAIRBANK TEXTILES IN COLLABORATION WITH PROCURE CIRCULAR

AMBIO-N supports business to the transition of a circular supply chain. In doing so organisations improve the environmental footprint of products and create a higher sustainable footprint across the industry.

AMBIO-N source and supply Fairbank Textiles with the raw material ‘fud’ (wool waste), which otherwise would’ve been thrown into landfill as waste from the production processes of other businesses. Collaboration between businesses, faciliated via AMBIO-N enables materials to be discovered, procured and kept in recirculation.